In the entertainment and architectural lighting industry, timing is everything. Whether it's the grand opening of a theater, a music festival, or an exhibition hall launch, delays in lighting fixture delivery can derail entire events. As the global supply chain faces increased disruptions from geopolitical shifts, extreme weather, port congestion, and post-pandemic bottlenecks, lighting professionals must adopt smarter logistics strategies to ensure timely arrival of gear.

Understanding the Causes of Global Logistics Delays

Delivery delays in fixture logistics often stem from a variety of interrelated challenges. These include:

1. Port Congestion and Container Shortages

Major ports such as Los Angeles, Rotterdam, or Shanghai frequently suffer from backlogs due to labor strikes, surges in freight volume, or infrastructure limitations.

2. Customs and Regulatory Hurdles

Inconsistent documentation, unclear labeling, or missing certifications can lead to customs holds — especially for electrical equipment with IP ratings or certifications.

3. Weather and Environmental Disruptions

Monsoons, typhoons, and winter storms can shut down ports and airports for days. Perishable lighting components like lithium batteries may require additional handling.

4. Last-Mile Failures

Even when containers arrive, local delays such as driver shortages, warehouse bottlenecks, or misrouted deliveries can cause unexpected hiccups.

Why Lighting Fixture Logistics Are Especially Time-Critical

Unlike general consumer goods, lighting fixtures are:

Event-driven: Missed delivery means missed performance.

Technically sensitive: Improper handling may cause damage to optics, motors, or programming interfaces.

Custom-packed: Shows often include pre-addressed fixtures, preloaded with firmware or cues, which can't easily be replaced.

Bulk-shipped: Entire productions ship as consolidated loads — one missing piece may compromise the whole rig.

Therefore, proactive logistics planning is non-negotiable.

Strategies to Reduce Delivery Delays

1. Build Time Buffers into Production Schedules

Never align delivery with install day. Allocate a minimum of 5–10 business days between planned arrival and setup, especially for cross-continental shipments.

2. Work with Specialized Freight Partners

Choose logistics companies experienced in handling stage or AV equipment. They understand the fragility and customs nuances of DMX/RDM-enabled gear or fixtures with integrated batteries.

3. Establish Regional Warehousing

Maintaining local stock (even partial kits) in key zones like Europe, Southeast Asia, or North America shortens lead times and provides fallback options.

4. Pre-Clear Customs with ATA Carnets or Pre-Approval

Using ATA Carnets for temporary imports, or working with local brokers to pre-clear documents (e.g., CE certification, MSDS sheets), drastically reduces hold risks.

5. Standardize Fixture Packaging and Documentation

Ensure every box includes:

Proper serial number labels

Fixture-specific data sheets

Safety declarations (for batteries, lasers, or strobes)

Country-of-origin labeling

Automation platforms can auto-generate such documentation based on SKU or project type.

Leverage Technology for Logistics Visibility

Real-Time Tracking Tools

Modern freight forwarders offer GPS or API-linked shipment dashboards that allow:

Live location tracking

Delay alerts (port dwell, customs check, weather reroutes)

Milestone updates (loaded on vessel, cleared customs, out for delivery)

Cloud-Based Order Coordination

Integrate logistics dashboards with cloud platforms used by designers, production managers, and clients to keep everyone updated on ETAs.

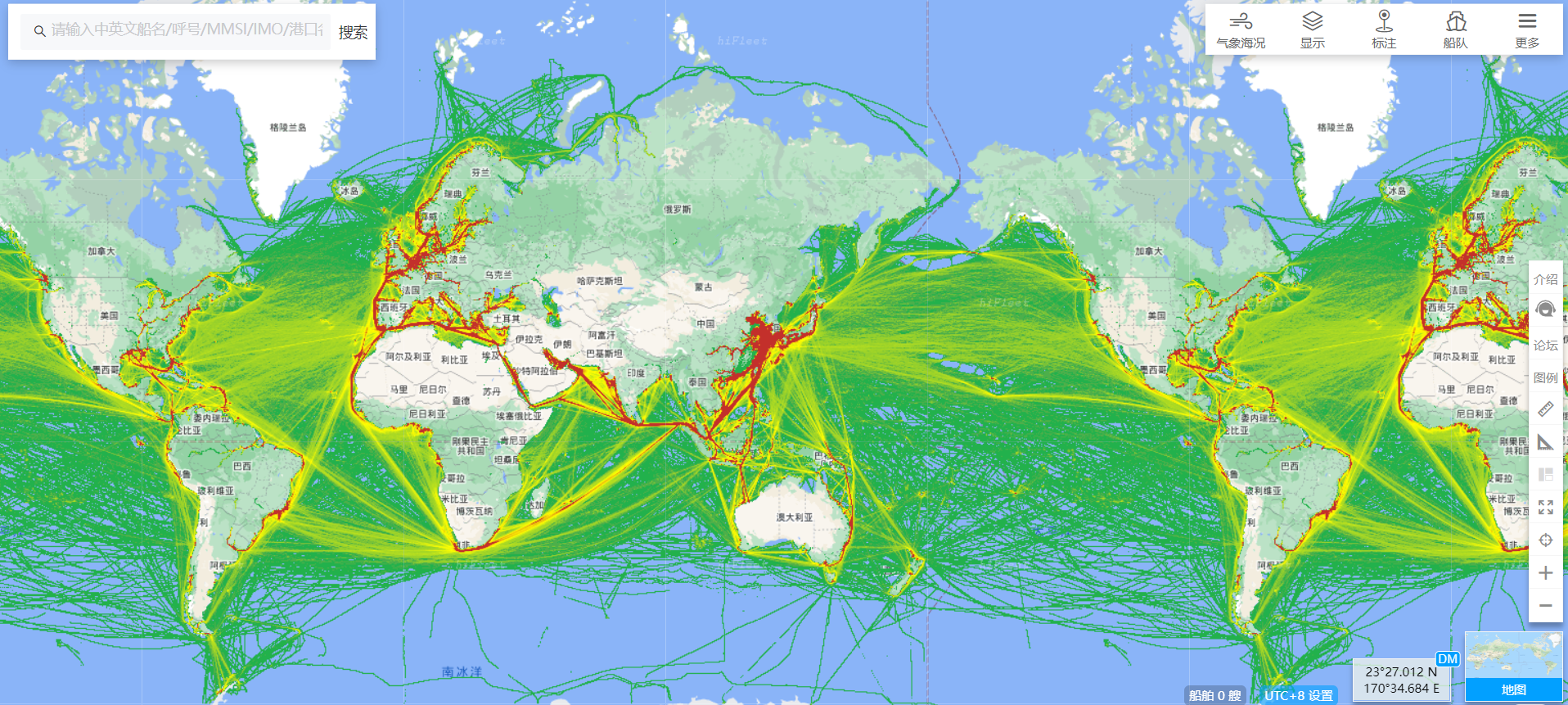

Predictive Analytics for Routing

Some platforms offer AI-based rerouting suggestions, which can preempt delays by recommending alternate ports, carriers, or hand-off times.

What to Do When Delays Occur

Even with planning, delays happen. Key steps:

Notify stakeholders early: Designers, rental houses, and crew must know immediately.

Activate backups: If using standardized gear, explore cross-rentals or alternate units locally.

Reschedule programming time: Adapt lighting rehearsals based on arrival.

Document incident: Keep records for insurance, freight claims, and future planning.

Conclusion

In a globalized, deadline-driven industry, avoiding delivery delays in fixture logistics requires foresight, agility, and technology. By building buffers, choosing experienced partners, and embracing cloud collaboration and real-time tracking, lighting professionals can reduce uncertainty — and ensure that shows start on time, every time.

READ MORE:

Blue Sea Lighting is an enterprise with rich experience in the integration of industry and trade in stage lighting and stage special effects related equipment. Its products include moving head lights, par lights, wall washer lights, logo gobo projector lights, power distributor, stage effects such as electronic fireworks machines, snow machines, smoke bubble machines, and related accessories such as light clamps.

Quick Links

For more questions subscribe to our email