Introduction: The Heart of Every LED Fixture

When evaluating the quality of a stage or architectural lighting fixture, one factor outweighs the rest: the LED chip. This microscopic component determines everything from brightness and color fidelity to heat resistance and operational lifespan. While housing, optics, and programming add value, chip sourcing is what sets premium fixtures apart from low-end alternatives.

This article explores the key factors that influence LED chip quality and how sourcing decisions directly affect lighting performance and reliability.

1. Understanding What an LED Chip Does

An LED chip (light-emitting diode) is a semiconductor that emits light when electric current passes through it. It converts electrical energy into photons through electroluminescence. These chips form the core of every LED light source, and they are typically housed on a substrate with a phosphor coating (for white light) and encapsulated in resin or silicone.

High-quality LED chips:

Emit consistent and high-lumen output

Show precise color rendering

Resist degradation over time

Handle thermal stress effectively

Low-grade chips, however, may flicker, fade quickly, or cause color shifts — problems that often manifest within months of use.

2. Key Factors in LED Chip Quality

a. Raw Materials and Manufacturing Standards

Silicon wafers, phosphor quality, and substrate materials all impact the chip’s durability and performance. Top-tier manufacturers invest in:

Ultra-pure gallium nitride (GaN)

Stable thermal substrates like copper or ceramic

Uniform phosphor layers for better white balance

The cleanroom standards, precision of deposition layers, and die-bonding techniques during manufacturing also determine chip lifespan and efficacy.

b. Binning and Sorting

Not all chips produced in the same batch perform equally. LED manufacturers use binning to classify chips based on attributes like:

Brightness (lumens)

Color temperature (Kelvin)

Voltage requirement

Chromaticity coordinates

Fixtures made with well-binned chips ensure uniform color and consistent brightness, critical for lighting designers working in multipoint or synchronized applications.

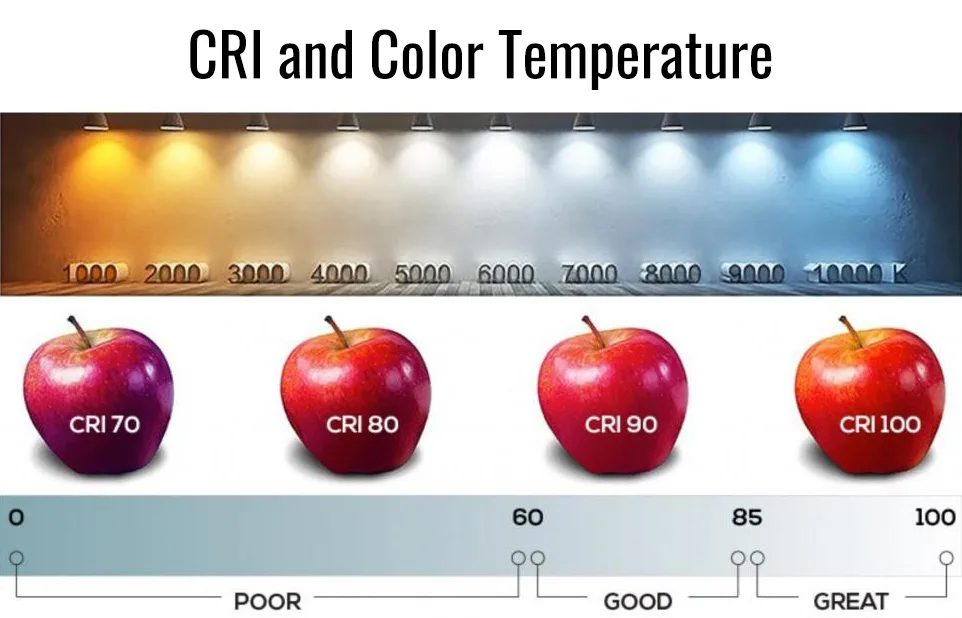

c. Color Rendering Index (CRI) and Spectral Quality

Fixtures using high-CRI chips reproduce colors more accurately, which is essential for:

Theater and concert lighting

Retail and art installations

Broadcast environments

LEDs with CRI above 90 offer near-natural light rendering. Quality sourcing ensures the spectral power distribution covers both visible and red-rich wavelengths, avoiding “washed-out” skin tones or incorrect fabric color perception.

3. Thermal Management and Chip Design

LED chips generate heat, and poor thermal management is the leading cause of early failure. Better chips feature:

Thermal vias in the substrate

Optimized junction-to-case thermal paths

Integration with external heatsinks

Some LED chip types are even COB (chip-on-board) or SMD (surface-mounted device) optimized for different fixture use cases. How the chip handles temperature spikes during operation will affect:

Light output stability

Color retention

Long-term durability

4. UV, IR, and Environmental Tolerance

Outdoor and stage lighting fixtures often face:

UV exposure from sunlight or other lights

High humidity or rain

Rapid thermal cycling (hot-to-cold transitions)

Well-sourced chips are encapsulated with resins that resist UV yellowing, corrosion, and moisture ingress. Poor-quality chips can become cloudy, cracked, or faded—making the fixture unusable even if the circuit board remains intact.

5. Compatibility with Control Systems

High-performance lighting fixtures must integrate with DMX, Art-Net, RDM, and various dimming protocols. Low-end chips often suffer from:

PWM flickering at low brightness

Delay or stutter when synced

Irregular step response in color transitions

By contrast, chips with stable response curves and current-handling tolerances offer smooth dimming and precise automation, particularly in large-scale shows or synced light arrays.

6. Supply Chain Integrity and Fake Chips

Unfortunately, counterfeit or mislabeled chips are a serious problem in the industry. These “ghost” chips often:

Use second-hand dies

Come from rejected wafer batches

Are rebranded with fake labels

Reputable fixture manufacturers audit their suppliers, require documentation like LM-80 and TM-21 test data, and even laser-mark verified chip lots. For buyers, this means longer lifespan, better reliability, and warranty-backed performance.

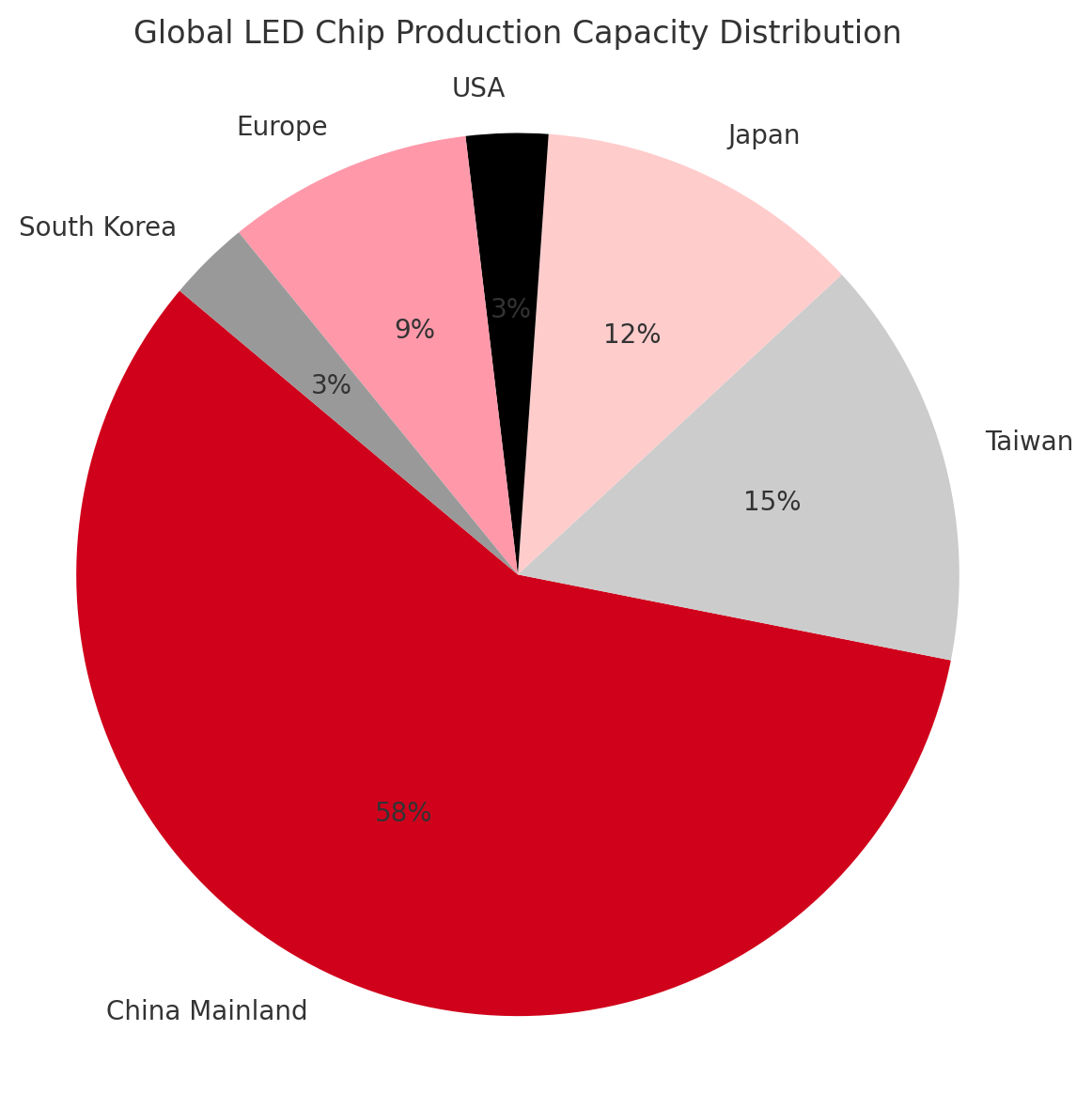

7. Regional Differences: Not All Chips Are Made Alike

Countries such as:

USA (Cree, Lumileds)

Japan (Nichia)

South Korea (Samsung, LG Innotek)

Germany (Osram)

lead the premium LED chip market with proprietary technologies and patented processes.

While China and Taiwan also produce high-quality chips, the market has a wider range from top-tier to low-budget options. Understanding sourcing origins helps fixture buyers make smarter trade-offs between cost and performance.

Conclusion: What Smart Buyers Should Look For

When evaluating lighting fixtures, ask these questions:

What brand or grade of LED chip is used?

Are there test reports (LM-80, TM-21)?

Is there a warranty on luminous flux degradation?

What’s the CRI and thermal resistance rating?

Choosing a fixture is choosing the performance heart of the light: the chip. Don’t be fooled by flashy housing or big lumen numbers — if the chip isn’t reliable, neither is the fixture.

READ MORE:

Blue Sea Lighting is an enterprise with rich experience in the integration of industry and trade in stage lighting and stage special effects related equipment. Its products include moving head lights, par lights, wall washer lights, logo gobo projector lights, power distributor, stage effects such as electronic fireworks machines, snow machines, smoke bubble machines, and related accessories such as light clamps.

Quick Links

For more questions subscribe to our email